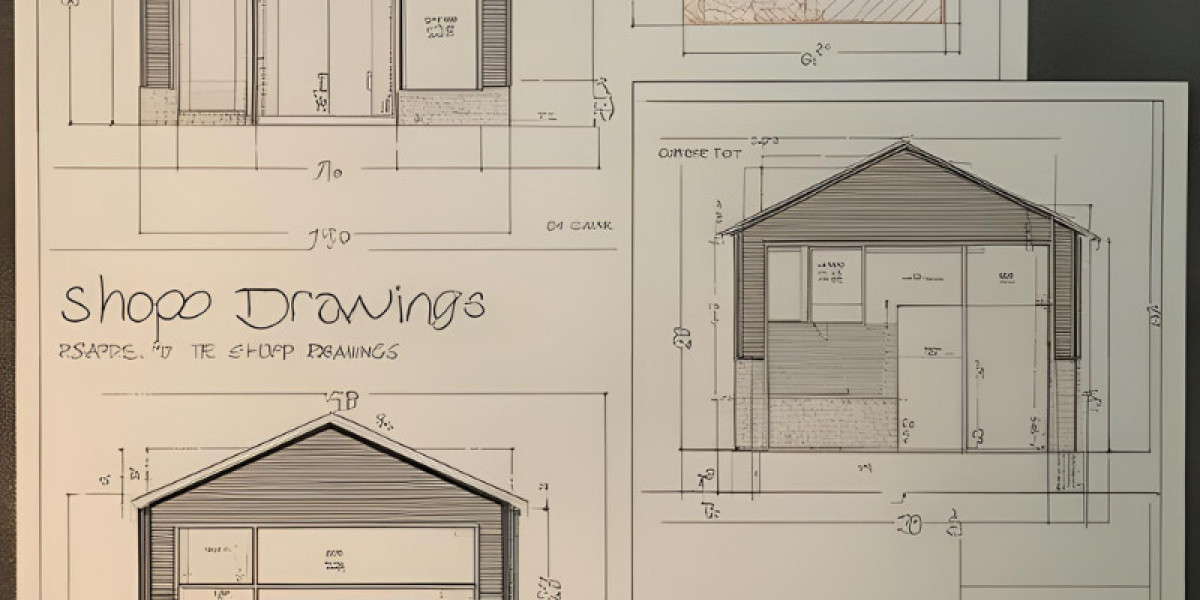

In the fast-paced world of construction, clarity and precision are not just desirable—they're essential. One of the most effective ways to ensure a smooth project workflow is through clear, detailed shop drawings.

These drawings act as the bridge between design intent and actual construction, translating architectural and engineering plans into actionable, buildable information. When shop drawings are thorough and unambiguous, they significantly reduce the need for Requests for Information (RFIs) and costly change orders.

In this blog, we’ll explore how high-quality shop drawings help minimize confusion, avoid delays, and ultimately save both time and money on a project.

What Are Shop Drawings and Their Purpose?

Shop drawings are detailed drawings created by contractors, fabricators, or manufacturers. These drawings show how different parts of a building or product will be made and installed. Unlike regular design drawings made by architects or engineers, shop drawings focus more on the “how” instead of the “what.”

Shop drawings often include measurements, materials, finishes, and installation details. They are used for items like cabinets, windows, doors, HVAC systems, and structural steel. Each drawing provides a clear guide for workers to build or install the item correctly.

The main purpose of shop drawings is to help ensure everything fits together properly during construction. They reduce mistakes by showing exactly how a piece will be built, how it connects to other parts, and how it should be installed. This saves time, avoids confusion, and prevents costly errors.

Another important purpose is communication. Shop drawings let contractors, architects, and clients review the final plan before making or installing anything. If there’s a mistake or a change needed, it can be fixed on the drawing first.

In short, shop drawings are a key part of any construction project. They act as a roadmap that helps turn design ideas into real structures. By showing detailed, step-by-step instructions, they help everyone work together smoothly and accurately.

The Common Issues Caused by Ambiguous or Incomplete Shop Drawings

Shop drawings are very important in construction and manufacturing. They show the exact details of how things should be made or installed. But when these drawings are unclear or incomplete, many problems can happen.

One major issue is miscommunication. If the drawings do not show enough detail or have confusing instructions, the workers may not understand what to do. This can lead to mistakes during production or installation.

Another problem is delays. When something is not clear in the drawing, the team must stop and ask questions. Waiting for answers or corrections takes time, which can slow down the whole project.

Cost overruns are also common. If mistakes are made because of poor drawings, they need to be fixed. Fixing errors costs money—both for extra labor and for new materials.

In some cases, safety risks may also occur. If the shop drawings do not show how something should be safely built or installed, it could lead to unsafe conditions at the site.

Lastly, client dissatisfaction is a real risk. When the final result doesn’t match the design vision due to bad drawings, the client may be unhappy and lose trust in the team.

In summary, clear and complete shop drawings are essential. They help everyone work together smoothly, avoid costly mistakes, and deliver a high-quality project on time. Good drawings save time, money, and effort—and ensure everyone is on the same page.

How Clear Shop Drawings Help Reduce RFIs

In construction projects, RFIs (Requests for Information) are common. They are questions sent by contractors or workers when they need more details or clarity about a design. Too many RFIs can slow down the project, increase costs, and cause confusion. One effective way to reduce RFIs is by using clear and detailed shop drawings.

Shop drawings are technical drawings that show how parts of the project will be built. These include measurements, materials, installation methods, and other important details. When these drawings are accurate and easy to understand, everyone involved knows exactly what to do. This reduces the need to ask questions later.

Clear shop drawings help avoid mistakes. For example, if a cabinet drawing shows the correct size, material, and hardware, the manufacturer can build it without guessing. The installer will also know exactly how and where to place it. This makes the whole process smooth.

Good drawings also improve communication between the design team, contractors, and fabricators. When all teams work from the same clear drawings, misunderstandings are less likely.

In short, clear shop drawings save time and money by preventing confusion. They make it easier for workers to do their jobs correctly the first time. Fewer RFIs mean fewer delays and better project outcomes. That’s why investing time and effort into creating high-quality shop drawings is always a smart choice for any construction project.

How Clear Shop Drawings Minimize Change Orders

Clear shop drawings play a big role in reducing change orders during construction projects. These detailed drawings show the exact dimensions, materials, and installation methods for items like millwork, furniture, or fixtures. When shop drawings are accurate and easy to understand, everyone involved—contractors, fabricators, and designers—can stay on the same page.

Change orders usually happen when something doesn’t match the plan, or when there is confusion about what needs to be built. This can delay the project and increase costs. But when shop drawings are clear, there’s less room for mistakes. Contractors can check all the measurements and materials before starting work. Any issues or conflicts can be found early and fixed before they become expensive problems on-site.

Good shop drawings also help get faster approvals from architects and clients. When everything is well-detailed and labeled, it’s easier for reviewers to give feedback or approval without back-and-forth discussions. This speeds up the workflow and helps keep the project on schedule.

In short, clear shop drawings act like a map for the construction team. They reduce misunderstandings, avoid costly rework, and help complete the project smoothly. Investing time in creating precise and simple shop drawings at the start can save a lot of time, money, and stress later.

The End Note

In conclusion, clear and detailed shop drawings are a crucial element in the success of any construction project. They serve as the vital link between design concepts and actual construction, providing precise instructions that help avoid confusion, reduce Requests for Information (RFIs), and minimize costly change orders.

By ensuring everyone—from contractors to fabricators to architects—works from the same accurate and comprehensive plans, clear shop drawings streamline communication, prevent costly mistakes, and keep projects on schedule and within budget.

Investing the time and effort to produce high-quality shop drawings upfront not only saves time and money but also fosters a smoother, more efficient construction process and ultimately leads to higher client satisfaction.