A mysterious figure emerges from the shadows of our modern landscape, sparking intense debates about faith, belief, and the nature of salvation. As rumors swirl around his sudden appearance in the Middle East, societies worldwide grapple with profound questions: Is he truly the messiah sent from above, or is he a cunning deceiver aiming to destabilize global order?

This intriguing saga is set to unfold over ten compelling episodes, each delving into diverse perspectives—from a young CIA operative, an Israeli intelligence officer, a Latino preacher and his Texan daughter, to a Palestinian refugee and the ever-watchful media. Their intertwined stories explore the complexities of trust, power, and faith in an era of uncertainty.

Crafted by acclaimed writer Michael Petroni, known for works like "The Chronicles of Narnia" and "The Book Thief," the series is brought to life through a collaboration with Emmy® winner Mark Burnett, MGM’s digital head, and renowned producer Roma Downey. The project promises a gripping narrative that challenges viewers to confront their own beliefs and biases.

Set to premiere on Netflix in 2019, the series aims to captivate audiences across the globe, inspiring questions about humanity’s deepest convictions. Will society accept the stranger claiming divine authority? How will the media shape public perception? Could such an event reshape the very fabric of our civilization?

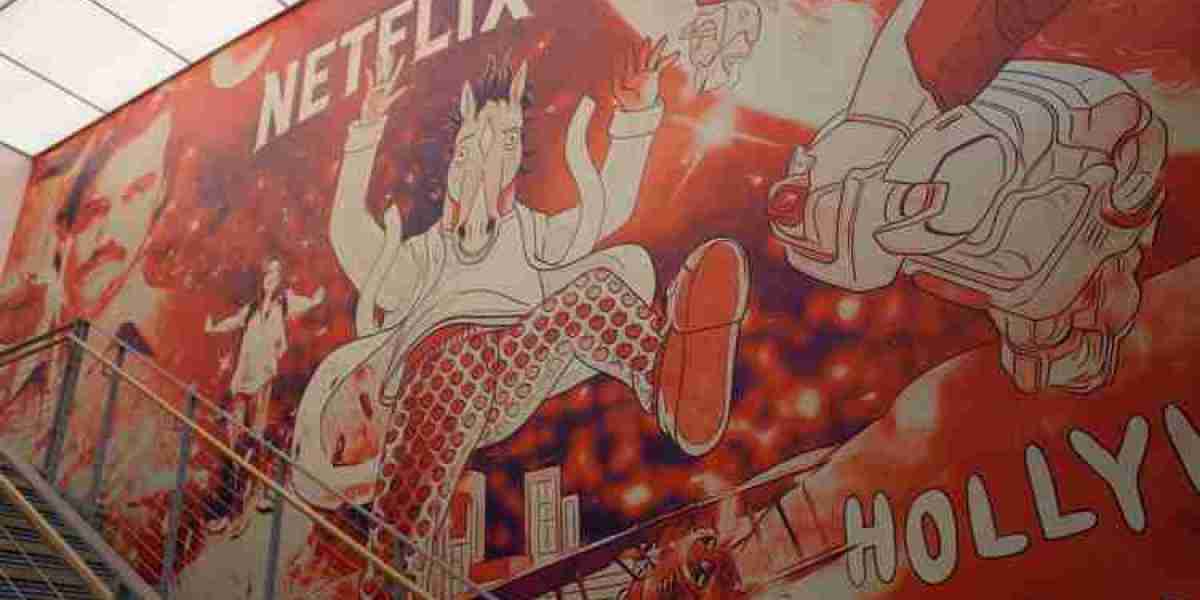

Netflix, the world’s leading platform for streaming entertainment, boasts over 109 million members worldwide, offering a vast array of original content accessible anytime, anywhere. As this new series approaches, it underscores Netflix’s commitment to delivering thought-provoking stories that resonate across cultures and faiths, inviting viewers to ponder what they believe—and why.

What is Netflix Unblocked?

Netflix is a popular streaming platform primarily used for watching a vast library of TV shows, movies, and original series on demand. Users sometimes encounter geographical restrictions, which is why the concept of Netflix unblocked becomes relevant. This process typically involves using tools like VPNs or proxy servers to bypass regional blocks and access a broader range of content from different countries.

Why Opt for SafeShell to Access Netflix Unblocked

If people want to access region-restricted content on Netflix by unblocking it, they may want to consider the SafeShell VPN. SafeShell VPN offers several compelling benefits that enhance your streaming experience. Firstly, it employs advanced encryption protocols to safeguard your online activities, ensuring your privacy remains protected from unwanted surveillance. Secondly, its unique ability to evade detection by Netflix's VPN and proxy systems allows for uninterrupted access to the full Netflix library, regardless of your location. Additionally, SafeShell VPN delivers blazing-fast connection speeds with high-speed servers optimized specifically for Netflix, minimizing buffering and enabling smooth, high-definition streaming. The platform also supports multiple device connections simultaneously—up to five—across various operating systems like Windows, macOS, iOS, and Android, making it versatile for all your devices. Moreover, features such as the exclusive App Mode allow users to unlock and explore content from multiple regions effortlessly, while the proprietary ShellGuard protocol guarantees uncompromised security during your online activities. Lastly, with a flexible free trial plan, users can experience all these benefits firsthand without any commitment, making SafeShell VPN an excellent choice for secure, high-speed, and unrestricted streaming.

How to Use SafeShell VPN to Unlock Netflix

To use SafeShell Netflix VPN for accessing global Netflix libraries, begin by securing a subscription through their official platform.

- Next, download and install the SafeShell application on your preferred device, ensuring compatibility with your operating system.

- Upon launching the app, log into your SafeShell account and select the specialized streaming mode to optimize performance for video services.

- Then, pick a VPN server from the list that corresponds to your desired geographic region, such as Japan or Germany, and initiate the connection.

- Finally, open Netflix in your browser or app, and you will immediately have access to that region’s exclusive content library.

Using SafeShell Netflix VPN reliably bypasses regional restrictions, allowing seamless streaming of shows and movies from anywhere in the world.