Smart liquid processing equipment is changing how large factories work. This equipment helps businesses handle liquids more easily and efficiently. At New Crown, we focus on creating tools that help companies produce liquids at a large scale. With smart technology, our machines can monitor and adjust to different conditions. This means they can work better and save time and money. When factories use smart liquid processing equipment, they can make more products while spending less on resources. This is a big deal because it helps businesses grow and compete in today's market.

What Are the Benefits of Smart Liquid Processing Equipment for Large-Scale Operations

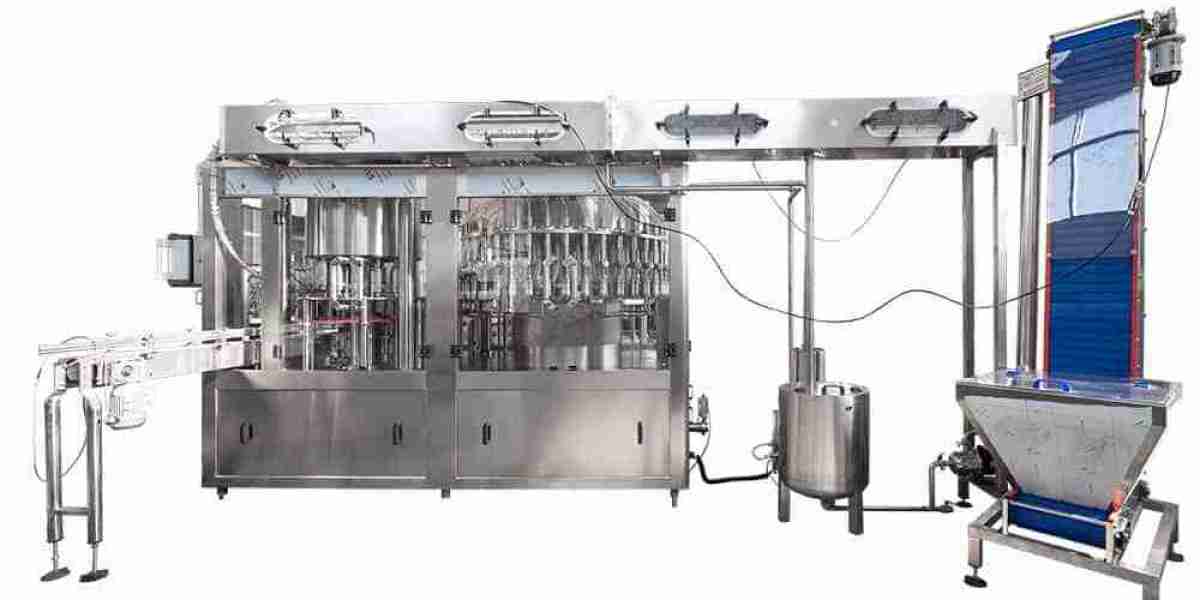

Using smart Water Filling Machine has many benefits for large factories. First, it saves time. Machines can adjust quickly to changes, which means less waiting. For example, if a factory needs to change a liquid's temperature, smart equipment can do this in seconds. This speed helps factories keep up with demand. Second, these machines are very accurate. They can measure and mix liquids precisely, which means there are fewer mistakes. This accuracy is important because it helps keep customers happy with the quality of products. Third, smart equipment can monitor itself. If something is wrong, it can alert workers before it becomes a big problem. This self-checking ability reduces downtime and repairs that can cost a lot of money. Finally, using smart technology is good for the environment. Many smart machines use less energy and produce less waste. By using resources more wisely, factories can help the planet while still making a profit. Overall, smart liquid processing equipment is a smart choice for large operations. It helps companies run better and meet the needs of their customers more effectively.

How Smart Liquid Processing Equipment Enhances Efficiency in Bulk Production

Smart liquid processing equipment plays an important role in making bulk production more efficient. One way it does this is by connecting to the internet, allowing machines to communicate with each other. This means they can share information in real time. For example, if one machine is running low on a liquid, it can tell the other machines to adjust their operations. This coordination helps prevent delays and keeps the production line moving. Another way these machines improve efficiency is through automation. Many tasks that workers used to do manually can now be done by machines. This frees up workers to focus on more complex tasks, like problem-solving or quality control. With fewer manual tasks, there is less chance of human error. Smart equipment also uses advanced sensors to collect data. This data helps managers understand how well the machines are working. They can see when a machine is running too slowly or using too much energy. With this information, they can make changes to improve efficiency. For example, if a machine is using more energy than normal, it might need maintenance. This kind of smart monitoring helps keep everything running smoothly. In the end, smart liquid processing equipment helps factories produce more with less waste and fewer mistakes. At New Crown, we are proud to be part of this exciting change in manufacturing.

When you run a big business that deals with liquids, like a factory or a food processing plant, choosing the right Carbonated Drink Filling Machine is very important. Smart liquid processing equipment helps you manage and control the liquids you work with, making everything smoother and more efficient. When looking for the right equipment, think about what your business does. Different businesses need different kinds of machines. For example, if you deal with food products, you need equipment that keeps everything clean and safe. New Crown offers equipment designed for many types of liquids, so you can find what fits your needs best. Also, consider how much liquid you process. If you have a large operation, you want equipment that can handle big amounts without breaking down. Look for machines that have strong materials and good reviews. Another thing to think about is technology. The best smart liquid processing equipment uses advanced technology. This means it can monitor what is happening in real time and make changes automatically. New Crown equipment comes with smart features that help you keep an eye on everything. Finally, think about the support you will get after buying the equipment. It’s important to have good customer service for help with any issues that may arise. New Crown is known for its excellent support, so you can feel confident in your choice. By considering these factors, you can find the right smart liquid processing equipment that will help your business run smoothly and efficiently.

Smart liquid processing equipment is essential for large-scale manufacturing for several reasons

First, it helps keep everything organized. When you have a lot of liquids to manage, it can quickly become chaotic. Smart equipment helps keep track of everything, from the amount of liquid being processed to the quality of the end product. This makes it easier to maintain high standards. With New Crown’s technology, you can monitor your liquids closely, ensuring that everything meets safety and quality guidelines. Second, smart equipment saves time and labor. In large operations, many workers are needed to manage processes manually. Smart liquid processing equipment can automate many tasks, which means you need fewer workers for routine jobs. This can save your business money and help your team focus on more important tasks. Additionally, smart equipment can help reduce waste. In large-scale production, wasting materials can be very costly. With precise control, smart equipment can minimize spills and errors, ensuring that you use every drop of liquid effectively. New Crown’s equipment is designed to be efficient, so you get the most out of your resources. Finally, smart liquid processing equipment can help you adapt to changes. In today’s market, trends and demands can shift quickly. With smart technology, you can adjust your processes quickly to meet new needs. This flexibility is crucial for staying competitive. Overall, smart liquid processing equipment is essential for large-scale manufacturing because it helps with organization, saves time and money, reduces waste, and allows for quick changes.

As we look to the future, several trends are shaping smart liquid processing in wholesale markets. One major trend is the increase in automation. More businesses are using machines that can do tasks without needing a lot of human help. This is great for large-scale operations because it reduces the chance of mistakes. New Crown is leading the way in this area by creating equipment that can automatically adjust to different conditions, making the processing of liquids more reliable and efficient. Another trend is the use of data. Smart liquid processing equipment now collects a lot of information while it works. This Juice Filling Machine data can help businesses understand what is happening in their processes. By analyzing this information, companies can make better decisions, improve their operations, and even predict future problems before they happen. New Crown equipment is designed to gather and share this data easily, helping businesses stay ahead. Sustainability is also becoming more important. People are more concerned about how products affect the environment. Smart liquid processing equipment can help reduce waste and energy use, making operations greener. Companies that adopt these technologies can attract more customers who care about eco-friendly practices. Finally, there is a growing trend toward customization. Every business is unique, and smart equipment is now being designed to meet specific needs. New Crown offers customizable solutions that cater to different industries, ensuring that every client gets the best possible equipment for their operations. As these trends continue to evolve, smart liquid processing will become even more important in wholesale markets, helping businesses thrive in a competitive landscape.