High-performance injection molds are important tools in the automotive industry. They help create parts that are strong, precise, and ready for use in cars and trucks. At Moldie, we know how vital it is to have high-quality molds that meet the tough demands of making car parts. These molds need to work well under pressure and create pieces that fit perfectly. When manufacturers use injection molding, they can make many parts quickly and efficiently. This means more cars can be produced, helping meet the demand for vehicles. In today’s world, where technology is always changing, using the right molds can make a big difference in quality and speed.

What Sets Them Apart for Automotive Applications

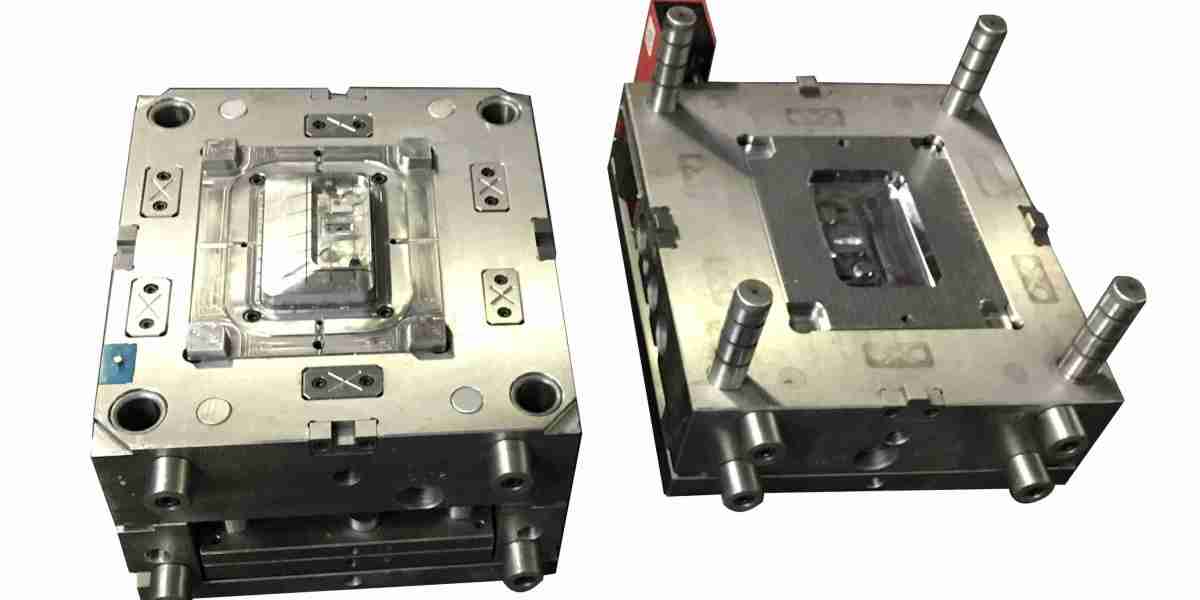

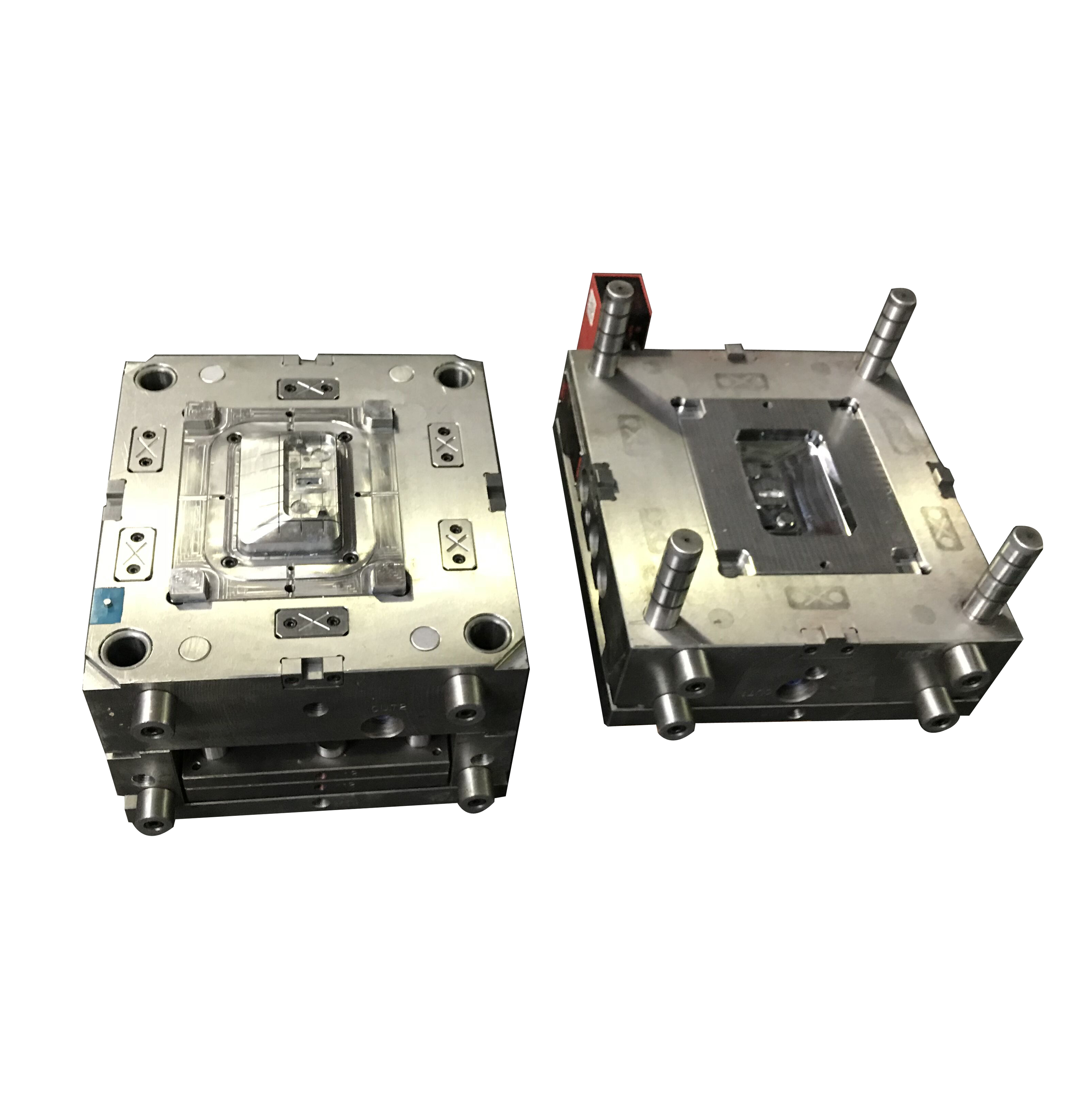

High-performance injection molding have special features that make them perfect for automotive applications. First, they are made from high-quality materials. These materials can withstand heat and pressure, which is essential when making car parts. For example, a car's dashboard needs to be tough and look good, and high-performance molds can create that. They can produce parts with great detail, which is very important for safety and design. The precision of these molds means that every piece fits together just right, which helps keep cars safe and running smoothly.

Another key aspect is the speed of production. High-performance molds can make many parts in a short time. This is crucial for car manufacturers who need to keep up with the fast pace of car sales. If a manufacturer can produce parts quickly, it means they can build more cars and respond faster to customer needs. Moreover, these molds are often designed to be used many times, which saves money in the long run. When the same mold can be used for thousands of parts, it reduces waste and costs.

Lastly, high-performance molds often come with advanced technology. Some molds have features like cooling channels that help control the temperature during the molding process. This can improve the quality of the parts and speed up production. At Moldie, we focus on creating molds with these advanced features so that our clients can produce high-quality automotive parts efficiently and effectively.

Where to Find Reliable Wholesale Suppliers of Automotive Injection Molds

Finding reliable wholesale suppliers for automotive injection molds can be a bit challenging, but it’s very important. First, you should look for companies that specialize in automotive parts. They often have the best experience and knowledge about what car manufacturers need. Ask other businesses for recommendations, as personal experiences can guide you to trustworthy suppliers.

Online research is another great way to find suppliers. Many suppliers have websites where they show their products and services. Look for reviews and ratings from other customers. This information can help you understand the quality of the molds they offer. Pay attention to their experience and how long they have been in business. A supplier with a long history is often a good sign of reliability.

Additionally, attending industry trade shows can be an excellent way to meet suppliers in person. These events often showcase the latest technology and products in the automotive industry. You can talk directly to suppliers, see their molds, and ask questions about their services. At Moldie, we encourage businesses to build relationships with suppliers. A good relationship can lead to better prices and service in the future.

Finally, always ask about warranties and support. A reliable supplier should offer some form of guarantee for their molds. This shows they believe in the quality of their products. If you follow these steps, you can find a trustworthy supplier that meets your needs for high-performance injection molds in the automotive industry.

How to Maximize Efficiency with High-Performance Injection Molds

When making parts for cars, using high-performance plastic injection molding is very important. These molds can help create strong and precise pieces that fit perfectly in vehicles. To maximize efficiency with these molds, it is crucial to plan everything carefully. First, choosing the right materials for the molds can make a big difference. Strong materials help the molds last longer and keep their shape, which is important for making many parts. Moldie knows this well and uses high-quality materials to ensure their molds are durable and effective.

Next, temperature control in the injection molding process is essential. If the temperature is too high or too low, the plastic may not fill the mold correctly. This can lead to waste and extra costs. By using machines that control the temperature accurately, companies can create better parts faster. Additionally, keeping the molds clean and well-maintained is key. Dust or leftover plastic can cause problems and slow down production. Moldie offers tips and tools to help businesses keep their molds in top shape, which helps them work better and faster.

Another way to improve efficiency is by using advanced technologies. For example, some companies use computer software to design their molds. This software helps them see how the mold will work before they even start making it. This way, they can fix any issues early on. Moldie uses this technology to ensure their molds are designed for maximum efficiency. Finally, training workers to understand how to use the molds properly is important. When workers know how to operate the machines and handle the molds, mistakes are less likely to happen. With all these strategies, companies can make the most out of their high-performance injection molds.

Where to Source Cost-Effective Wholesale Injection Molds for Automotive Parts

Finding cost-effective wholesale injection molds for automotive parts can help businesses save money and increase their profits. One of the best places to start is by looking online. Many websites offer a variety of molds for different types of automotive parts. Moldie has an extensive catalog that showcases their molds, making it easy for companies to find what they need at a good price. By comparing different options, businesses can choose molds that fit their budget without sacrificing quality.

Another option is to attend trade shows or industry events. These gatherings allow businesses to meet manufacturers and suppliers in person. At these events, companies can see the molds up close and ask questions. This can help them understand the value of the molds and find the best deals. Moldie often participates in such events, showcasing their high-quality molds and answering questions from potential customers. This personal touch can make a big difference when choosing the right supplier.

Additionally, reaching out to local suppliers can be a smart move. Sometimes, local businesses offer competitive prices and can provide faster shipping. This means companies can get their molds quickly and start production sooner. Moldie is committed to working with local suppliers when possible, ensuring that customers receive their molds without long wait times. Finally, it’s important to read reviews and get recommendations from other businesses. Hearing about other companies' experiences can help make informed decisions. By exploring these different options, businesses can find cost-effective wholesale injection molds that meet their needs.

What Innovations Are Driving the Future of Automotive Injection Molding

The future of automotive injection molding is exciting because of many new innovations. One major change is the use of advanced materials. Today, companies are experimenting with lighter and stronger plastics. These materials can be used to make parts that are not only durable but also help improve fuel efficiency in vehicles. The injection molding products is at the forefront of using these new materials, ensuring that their molds can handle the latest advancements in automotive technology.

Another important innovation is the use of automation. Many companies are now using robots andHigh-Performance Injection Mold machines to help with the injection molding process. This makes production faster and can reduce errors. By automating some parts of the process, workers can focus on other important tasks, which helps the entire production run smoothly. Moldie invests in the latest technology to make sure their injection molds are efficient and reliable.

Additionally, companies are now using 3D printing to create prototypes of their molds. With 3D printing, businesses can quickly make a model of a part before they create the final mold. This allows them to test and make changes easily, saving time and resources. Moldie incorporates 3D printing in their design process, which helps them respond faster to customer needs and create better molds. Finally, the rise of sustainable practices is changing the way automotive parts are made. Many companies are looking for ways to reduce waste and recycle materials. Moldie is dedicated to being environmentally friendly, ensuring that their processes help protect the planet. By embracing these innovations, the future of automotive injection molding looks bright and full of possibilities.