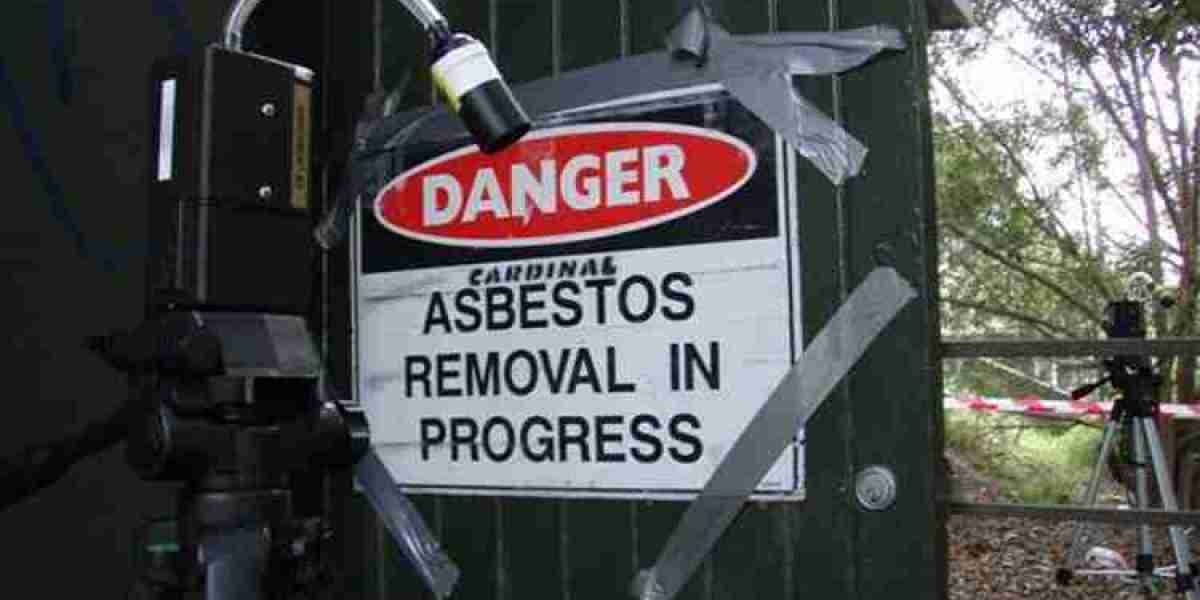

Asbestos remains one of the most serious health hazards in the construction industry, particularly when working on older buildings and infrastructure. Although its use has been banned in many countries, asbestos-containing materials are still present in thousands of commercial, industrial, and residential structures. During construction, renovation, or demolition activities, these materials can be disturbed, releasing microscopic asbestos fibres into the air. This is where asbestos air monitoring becomes critically important.

Understanding the Risk of Asbestos Exposure

Asbestos fibres are extremely small and invisible to the naked eye. When inhaled, they can lodge deep in the lungs and remain there for years, leading to serious health conditions such as asbestosis, lung cancer, and mesothelioma. These diseases often develop decades after exposure, making prevention the only truly effective protection.

Construction projects are especially high-risk environments because activities like cutting, drilling, sanding, or demolishing building materials can easily release airborne fibres. Without proper monitoring, workers and nearby occupants may be unknowingly exposed to dangerous levels of asbestos.

What Is Asbestos Air Monitoring?

Asbestos air monitoring is the process of sampling and analysing air to measure the concentration of asbestos fibres present in the environment. This is typically carried out by trained and independent professionals using specialised equipment. Air samples are collected during various stages of construction work and analysed in accredited laboratories to determine fibre levels.

The results help confirm whether control measures are effective and whether the site remains safe for workers and the public.

Protecting Worker Health and Safety

The primary reason asbestos air monitoring is critical during construction projects is worker protection. Even with strict safety procedures in place, unexpected fibre release can occur. Air monitoring acts as an early warning system, identifying elevated fibre levels before they pose a serious health risk.

By continuously or regularly monitoring the air, site managers can take immediate action if fibre concentrations exceed safe limits. This may include stopping work, improving containment measures, upgrading personal protective equipment (PPE), or revising work methods.

Ensuring Legal and Regulatory Compliance

In many regions, including Australia, asbestos air monitoring is not just best practice—it is a legal requirement for certain types of work. Regulations often mandate air monitoring during asbestos removal, particularly for friable asbestos or high-risk activities.

Failure to comply with asbestos regulations can result in severe penalties, project delays, and legal action. More importantly, non-compliance puts lives at risk. Proper air monitoring demonstrates due diligence and helps construction companies meet workplace health and safety obligations.

Supporting Safe Asbestos Removal and Clearance

Asbestos air monitoring plays a vital role throughout the entire lifecycle of asbestos-related construction work. This includes:

- Background monitoring before work begins to establish existing fibre levels

- Control monitoring during active work to ensure safety measures are effective

- Clearance monitoring after work is completed to confirm the area is safe for reoccupation

Clearance air monitoring is especially important, as it provides documented evidence that asbestos fibres have been reduced to acceptable levels. Without this confirmation, reopening a site could expose workers, occupants, or the public to residual contamination.

Protecting the Public and Surrounding Areas

Construction sites are rarely isolated. Nearby offices, homes, schools, and public spaces can all be affected if asbestos fibres migrate beyond the work zone. Asbestos air monitoring helps ensure that containment systems such as enclosures, negative pressure units, and barriers are functioning correctly.

By verifying that fibre levels outside the work area remain within safe limits, air monitoring protects not only construction workers but also the wider community.

Building Trust and Project Confidence

Beyond safety and compliance, asbestos air monitoring provides reassurance to clients, regulators, and workers. Transparent monitoring and reporting show that health risks are being taken seriously and managed professionally.

For construction companies, this builds trust, reduces disputes, and helps maintain a strong safety reputation. It also minimises the risk of costly project interruptions caused by uncontrolled asbestos exposure.

Conclusion

Asbestos air monitoring is a critical component of safe construction practices whenever asbestos-containing materials may be present. It protects worker health, ensures legal compliance, supports effective asbestos removal, and safeguards the surrounding community. In an industry where safety cannot be compromised, asbestos air monitoring is not optional—it is essential. By investing in proper monitoring, construction projects can proceed with confidence, responsibility, and long-term protection for everyone involved.