Market Overview:

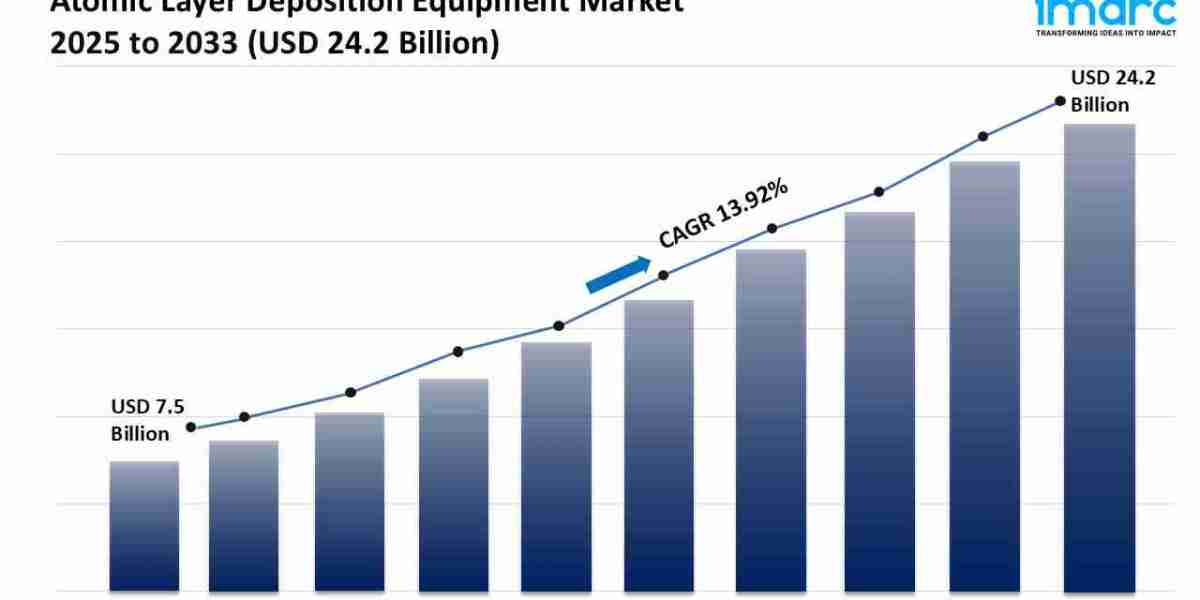

The atomic layer deposition equipment market is experiencing rapid growth, driven by rising demand for miniaturized electronics, expansion in renewable energy applications, and growth in medical device manufacturing. According to IMARC Group's latest research publication, "Atomic Layer Deposition Equipment Market Report by Product (Metal ALD, Aluminium Oxide ALD, Plasma Enhanced ALD, Catalytic ALD, and Others), Application (Semiconductors, Solar Devices, Electronics, Medical Equipment, and Others), and Region 2025-2033", the global atomic layer deposition equipment market size reached USD 7.5 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 24.2 Billion by 2033, exhibiting a growth rate (CAGR) of 13.92% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/atomic-layer-deposition-equipment-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Atomic Layer Deposition Equipment Market

- Rising Demand for Miniaturized Electronics

The ongoing desire for smaller, more powerful electronic devices is an important factor influencing the Atomic Layer Deposition (ALD) equipment marketplace. As consumer demand rises for smaller devices (smart phones, wearables and IoT), manufacturers of those devices are in need of extraordinarily precise and uniform thin-film coating for a variety of tiny components to ensure performance and reliability. ALD provides great uniformity for depositing ultra-thin, conformal films on complex 3D geometries which makes it an important tool for building advanced semiconductor chips and microelectromechanical systems (MEMS). For example, companies such as Samsung and TSMC produce high-performance chips for 5G-enabled devices that rely on ALD and yes, there is an absolute need for new technology for faster, smaller electronics in a connected world.

- Expansion in Renewable Energy Applications

The worldwide shift to sustainable energy solutions contributes substantially to the ALD equipment market. ALD is important for the efficient production of solar cells and lithium-ion batteries, two essential technologies for renewable energy systems. ALD uses thin films deposited at the atomic level to enhance the energy conversion efficiency and battery life of solar and renewable storage. Producing high-efficiency photovoltaic cells would not have been possible without ALD. For example, Chinese photovoltaic manufacturers now use ALD to deposit passivation layers to improve energy conversion on PERC solar cells to achieve maximum energy production from the sun. Worldwide government incentives for clean energy are expected to significantly increase the demand for ALD equipment for solar and battery manufacturing applications.

- Growth in Medical Device Manufacturing

The medical industry's reliance on advanced material & precision coatings has induced demand for the new generation of ALD equipment. These applications take advantage of the unique ability of ALD technology to deposit biocompatible and ultra-thin coatings on medical implants and diagnostic devices improving durability and performance. For example, ALD is used to coat stents and orthopedic implants that must perform in biological extremes while keeping some level of compatibility with the body. The increase in demand associated with minimally invasive devices, as well as advanced diagnostics, and heightened expectation for innovations in healthcare are driving the medical sector's shift towards using ALD. Companies like Beneq have devoted recent effort to developing ALD solutions for medical applications to help meet the ever-present demand for performance, reliability, and high quality coatings in the medical industry.

Key Trends in the Atomic Layer Deposition Equipment Market

- Advancements in Plasma-Enhanced ALD Technology

Plasma-Enhanced ALD (PEALD) is changing the game with respect to faster and more adaptive deposition processes. PLALD is allowing users to be more flexible with the temperature during a deposition process, allowing for lower processing temperatures, similar to plasma assisted CVD. Compared with the conventional thermal ALD, PEALD is ideally suited for low-temperature applications and thin-film deposition on sensitive substrates like polymers and on flexible electronics. This trend is particularly significant in semiconductor manufacturing where use of PEALD contributes to the complexity of structures (a.k.a., CMOS and MOSFET). For example, ASM International's PEALD systems are gaining a lot of traction for being able to deposit high-quality films with a lower temperature - which is making the chip production process more efficient, and even giving ALD usage broader applications for the next-generation of devices.

- Integration with Other Deposition Technologies

An important trend in the ALD equipment market is the combination of ALD with other deposition techniques (such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD)) to create hybrid systems. These systems are hybrid because customers can determine a lot of flexibility in how the deposition processes will be performed and how they might be optimized (whether in the film chemistry or the unit operation). For example, Veeco Instruments has hybrid platforms that combine ALD and MOCVD for high-performance photonics device production that are designed to improve film quality by enabling both different film chemistries and procedural combinations of ALD and MOCVD throughout an item's build process to enhance production throughput and improved manufacturing. This trend and hybridization of devices is a push to accommodate today's demand for "versatile" and "efficient" high throughput systems within modern large scale manufacturing environments.

- Focus on Sustainable and Eco-Friendly Processes

Sustainability is becoming more and more of a focus in ALD equipment market. Equipment manufacturers are developing sustainable processes to meet environmental regulations and environmentally conscious customers. There is a lot of innovation with activity in the ALD space dedicated to reducing energy consumption and waste in the manufacturing of substrates through the improved use of precursors and improving process efficiency. Companies such as Forge Nano are looking at how to use more sustainable ALD processes in battery coatings to lessen the environmental impact of the production of lithium-ion batteries. In response to current industries moving toward more sustainable manufacturing, ALD equipment manufacturers have made significant investments into R&D initiatives to develop low-impact solutions consistent with global objectives that combat climate change and produce environmentally friendly technologies.

Leading Companies Operating in the Global Atomic Layer Deposition Equipment Industry:

- Arradiance LLC

- ASM International

- Beneq Oy

- CVD Equipment Corporation

- Forge Nano Inc.

- Kurt J. Lesker Company

- Lam Research Corporation

- Oxford Instruments plc

- Picosun Oy (Applied Materials Inc.)

- SENTECH Instruments GmbH

- Veeco Instruments Inc.

- Wonik IPS Co. Ltd.

- Tokyo Electron Limited

Atomic Layer Deposition Equipment Market Report Segmentation:

Breakup By Product:

- Metal ALD

- Aluminum Oxide ALD

- Plasma Enhanced ALD

- Catalytic ALD

- Others

Breakup By Application:

- Semiconductors

- Solar Devices

- Electronics

- Medical Equipment

- Others

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302