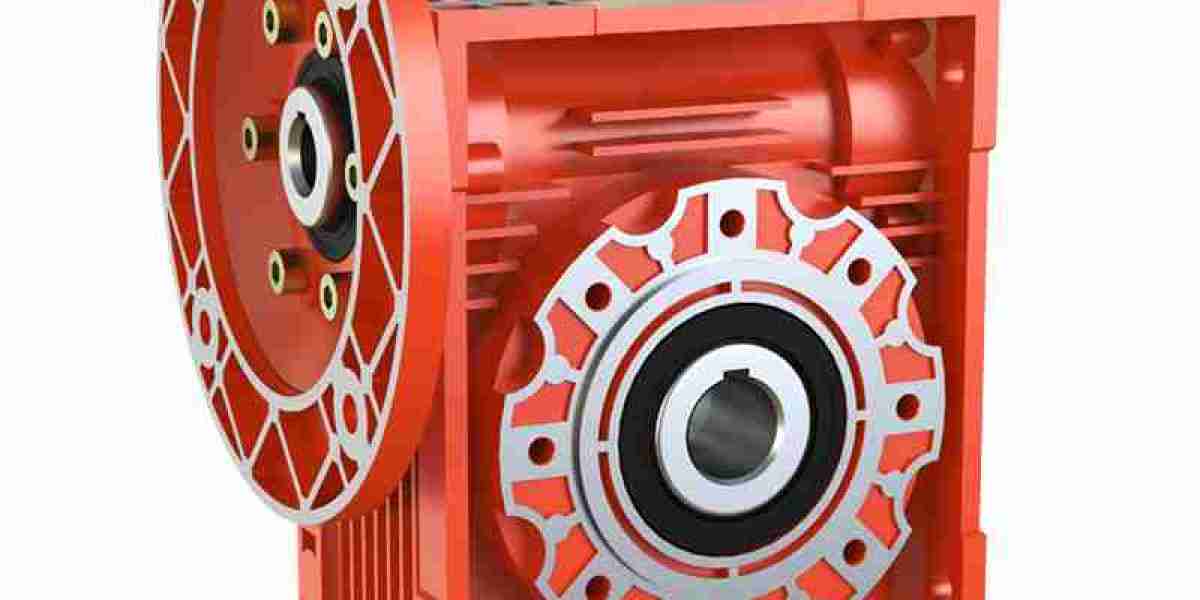

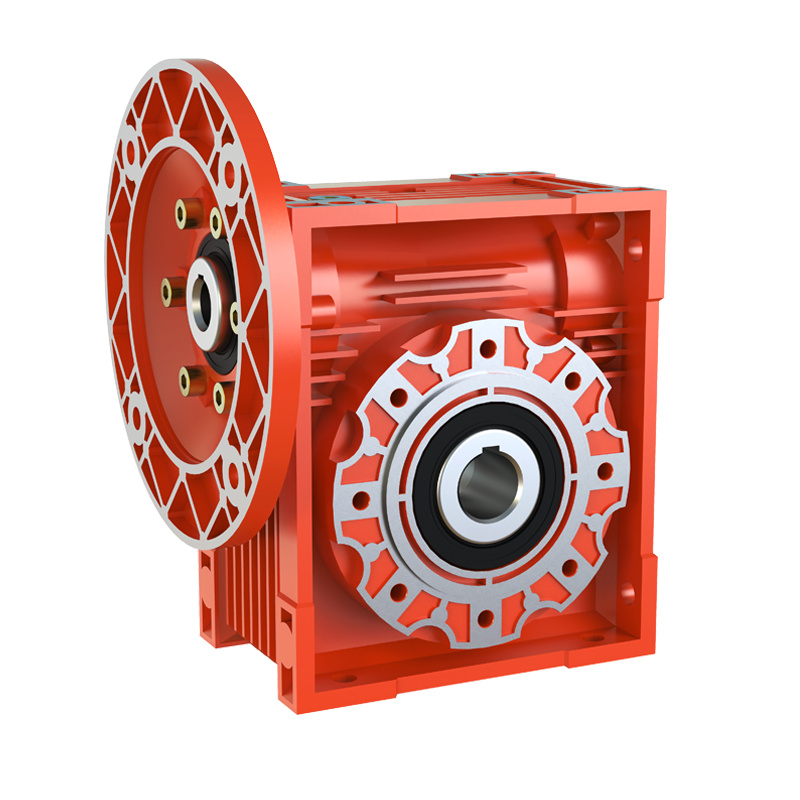

At Zhejiang Wuma Drive Co., Ltd., we take pride in crafting custom worm gear boxes that meet the unique needs of our customers. Our experience in industrial manufacturing allows us to deliver products that not only work perfectly but also last a long time. A worm gear box is a special device that can help machines change their speed and direction. It's essential for many industries, like automotive, food processing, and robotics. With Wuma, customers can get the specific size and features they need, making their machinery more effective. We focus on working closely with our clients to understand what they want, so we can create gear boxes that fit just right. Our skilled team makes this possible, using top-quality materials and advanced techniques. Custom designs give companies the ability to enhance their operations and improve productivity. When a business chooses our custom worm gear boxes, they are making a smart choice to invest in quality and efficiency.

Custom Worm Gear Box Solutions Tailored to Your Needs

At Wuma, we know that one size does not fit all. Each business has different machines and goals, which is why custom solutions are so important. Our team works with every client to determine their specific requirements from size and shape to the materials used. For instance, some customers might need gear boxes that can handle heavy loads, while others may want lightweight models for smaller machines. It’s not just about making a product; it’s about creating something that truly fits. A huge part of our work includes listening to the customer, understanding their challenges, and putting our heads together to find the best solution. This collaboration results in worm gear boxes that perform better and last longer. We have the tools and skills to make this happen. For example, if a factory needs a gear box that can resist heat or chemicals, we can use special materials designed for those conditions. These custom Worm Gearbox solutions lead to improved efficiency in machines because they do exactly what customers need them to do. People return to us, not just for the products, but because they experience firsthand how we care about their success. It’s rewarding to see the impact our gear boxes have on their productivity.

Quality Meets Affordability

At Wuma, we believe that high quality shouldn't mean high prices. Our goal is to make worm gear boxes that are reliable while still being easy on the budget. We focus on finding the best materials and methods to keep our costs down without cutting corners. Because we manufacture in-house, we control every step of the process. This means we can ensure that each gear box meets our high standards. For example, we use modern technology and skilled workers to create products that are strong and efficient. A well-made gear box can save money in the long run by reducing wear and tear on machines, meaning fewer replacements and repairs needed. Beyond that, we offer competitive prices that can fit different budgets. We know how important it is for businesses to manage their spending while still getting quality products. That’s why we aim to provide solutions that combine affordability with performance. Our customers often tell us they appreciate how we keep them in mind when designing and producing our gear boxes. They can trust that they’re getting the best value for their investment, which ultimately helps their businesses grow. In a world where every dollar counts, we stand firm in our commitment to producing gear boxes that balance quality and price perfectly.

What Makes Zhejiang Wuma Drive Co., Ltd. Stand Out in Gear Box Manufacturing

Zhejiang Wuma Drive Co., Ltd. is a special company that makes worm gear boxes. These Helical Worm Gearboxes are important because they help machines work better. Wuma stands out because of its focus on quality and customer service. First, the company uses high-quality materials to build their gear boxes. This means that when you buy a product from Wuma, you can trust that it will last a long time and work well. Wuma pays attention to every detail during the manufacturing process. They have skilled workers who know how to make gear boxes that are strong and reliable. The company also uses advanced technology in its factories. This technology helps them build gear boxes that are precise, meaning all the gears fit together perfectly. This leads to smoother operations and less chance of problems.

Another reason Wuma is special is because they listen to their customers. They understand that different customers have different needs. This is why they offer many options for customization. If a customer needs a worm gear box for a specific machine or task, Wuma can create it just for them. This flexibility is one of the things that sets Wuma apart from other manufacturers. Customers appreciate this because it makes their work easier. They don’t have to settle for a product that is only close to what they need. Wuma helps them find the exact solution for their challenges.

Additionally, Wuma is committed to keeping up with the latest industry trends. They invest in research and development to improve their products. This means they are always looking for ways to make their gear boxes better and more efficient. When new technologies come out, Wuma is quick to adopt them. This constant improvement keeps Wuma at the top of the gear box manufacturing industry and ensures that they provide the latest and best products to their customers.

Common Usage Issues with Worm Gear Boxes and How to Overcome Them

Worm gear boxes are very useful, but sometimes they can have problems. Understanding these common issues can help users solve them easily. One of the most frequent problems is overheating. When a worm gear box gets too hot, it can stop working properly. This often happens when the gear box is overloaded or not lubricated enough. To fix this, users should make sure they are not putting too much weight on the gear box. It is also important to check the lubrication regularly. Adding the right amount of oil or grease can help keep everything cool and running smoothly.

Another issue people face is noise or vibration from the worm gear box. This can be annoying and it might mean there is a problem inside. Usually, this happens because the gears are not aligned correctly or are worn out. To overcome this issue, users should regularly check the alignment of the gears. They should also inspect them for signs of wear. If they find damaged gears, they should replace them to prevent further problems.

Sometimes, people may notice that their worm gear box does not provide enough torque or power. This means the machine might not work as well as expected. This can happen if the gear box is not the right size for the job it’s being used for. To fix this, users may need to consult with experts, like those at Wuma, who can help them choose the right gear box for their specific needs. If they realize that they need a custom gear box, it's always good to reach out to a company like Wuma, which can design one specifically suited to their requirements.

By addressing issues like overheating, noise, or insufficient power, users can make their worm gear boxes work better. Regular maintenance and consulting with professionals will lead to a better experience. Customers should not hesitate to contact Wuma with any concerns. Wuma is always ready to help and provide solutions to any problems.

How Custom Design Enhances Performance in Worm Gear Boxes

Custom design is very important when it comes to worm gear boxes. Each machine and task is different, so having a standard one-size-fits-all gear box might not always work well. With custom designs, companies like Wuma can create gear boxes that are perfect for specific needs. This can greatly enhance the performance of a machine. For example, if a company needs a worm gear box for a heavy-duty application, Wuma can design a box that can handle the extra load. Making sure the gear box is the right size and strength can help it work more efficiently.

Another advantage of custom-designed worm helical gearbox is that they can improve energy efficiency. When a gear box is made specifically for a task, it can use less energy to perform its job compared to a standard option. This saves money in the long run and helps protect the environment because less energy is consumed. Wuma uses advanced software and technology to create 3D models of custom gear boxes. This helps them visualize how the gear box will work before they even start making it.

Wuma also understands that customers might have their own specifications or unique tasks. By collaborating with customers, Wuma can design a gear box that not only meets but exceeds expectations. When users demonstrate what they need, Wuma’s engineers can brainstorm ideas and come up with the best solutions. This custom approach helps build trust between Wuma and its customers and shows that Wuma cares about their success.

In addition to better performance, custom gear boxes can also lead to longer lifespans. A gear box designed precisely for its intended job will experience less wear and tear. This means it will not need to be replaced as quickly, saving customers money on repairs and replacements. custom design plays a crucial role in enhancing the performance of worm gear boxes at Wuma. Customers benefit from improved efficiency, tailored solutions, and long-lasting products which help them succeed in their tasks.