A Jar Preform mold plays a central role in the creation of plastic jars that appear in kitchens, bathrooms, and laboratories. While the finished container draws attention, the preform stage determines much of its future performance. The mould gives shape to the preform, setting the foundation for wall thickness, neck accuracy, and overall structure.

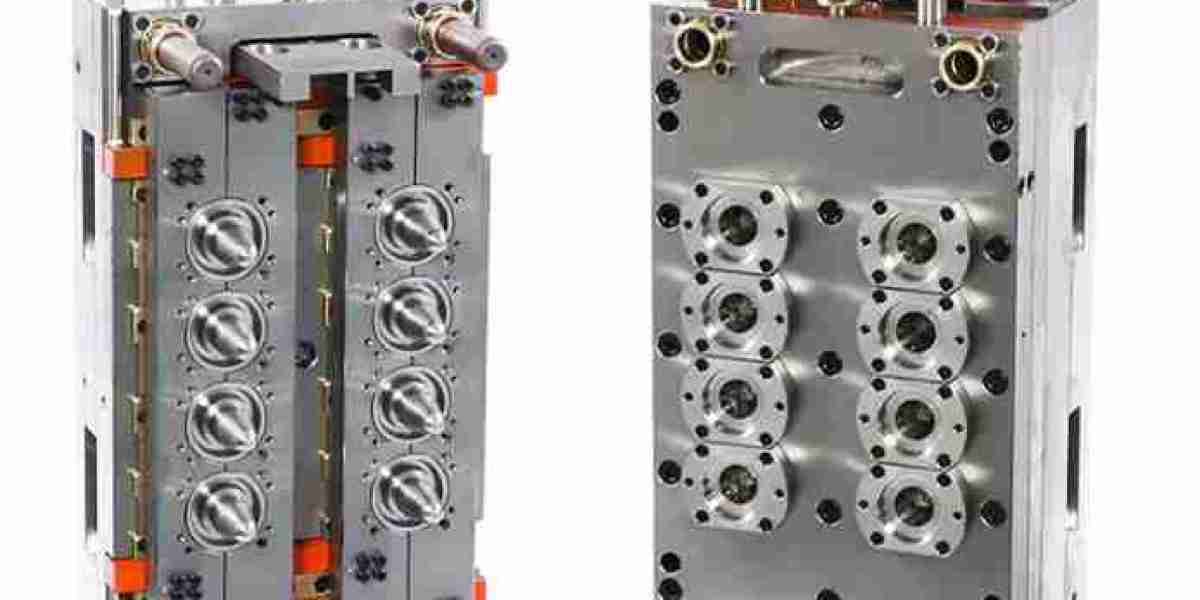

Accuracy matters from the first injection. A Jar Preform mold must guide molten material into cavities evenly, allowing each preform to cool in a controlled manner. Balanced flow helps ensure that every piece behaves predictably during later blowing stages. When this balance is achieved, the final jar shows uniform walls and stable dimensions.

Material behavior adds another layer of complexity. Different resins react to heat and pressure in unique ways. A Jar Preform mold needs to support smooth filling while avoiding stress points. Cooling channels and cavity layout influence how the material settles, which directly affects clarity and strength.

Durability also defines mould performance. A Jar Preform mold is expected to run for long cycles while maintaining consistent output. Wear-resistant components and well-polished surfaces help protect cavity shape over time. This stability supports reliable scheduling and reduces unexpected interruptions.

Design flexibility supports diverse packaging needs. Jars vary in size, neck finish, and application. A thoughtfully designed Jar Preform mold can accommodate these variations through interchangeable inserts or adjusted cavity layouts. This adaptability allows producers to respond to changing market demands without extensive retooling.

Production efficiency depends on smooth operation. Consistent ejection, stable temperature control, and predictable cycle times help maintain steady output. A Jar Preform mold that performs reliably contributes to reduced waste and better material usage.