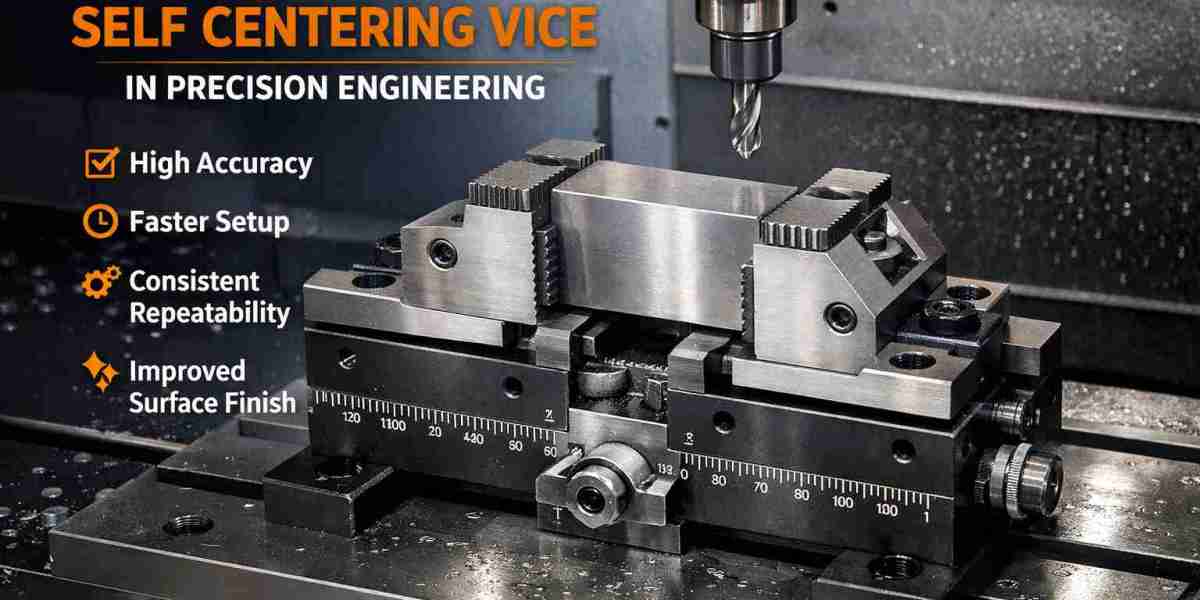

Top Benefits of Using a Self-Centering Vice in Precision Engineering

Precision engineering is all about accuracy, repeatability, and efficiency. Whether you are working in a CNC machine shop, tool room, or manufacturing unit, workholding plays a critical role in final output quality. One tool that has become increasingly popular in modern machining environments is the self-centering vice. Designed to automatically align workpieces along a central axis, this vice delivers consistent results with minimal setup effort.

In this blog, we’ll explore the top benefits of using a self-centering vice in precision engineering and why it has become a must-have for professionals who demand high accuracy.

What Is a Self-Centering Vice?

A self-centering vice is a precision workholding device where both jaws move symmetrically toward or away from the center when tightened. This ensures that the workpiece is automatically aligned along the machine spindle’s centerline. Unlike conventional vices that require manual alignment, self-centering vices eliminate guesswork and reduce setup time.

Importance of Workholding in Precision Engineering

In precision engineering, even a minor misalignment can lead to dimensional errors, poor surface finish, and material wastage. Reliable workholding ensures:

Accurate machining

Reduced vibration

Consistent tolerances

Improved tool life

A self-centering vice directly addresses these requirements, making it an essential tool for high-precision applications.

Key Benefits of Using a Self-Centering Vice

Improved Machining Accuracy

One of the biggest advantages of a self-centering vice is its ability to position the workpiece perfectly at the center every time. This automatic alignment significantly reduces positioning errors, ensuring tight tolerances and repeatable accuracy across multiple components.

Reduced Setup Time

Traditional vices often require manual measurement and adjustment to center the job. A self-centering vice eliminates this step, allowing operators to clamp the workpiece quickly and start machining. This reduction in setup time boosts productivity, especially in batch production.

Consistent Repeatability

Repeatability is crucial in precision engineering. Self-centering vices ensure that each workpiece is clamped in the same position every time. This consistency helps maintain uniform dimensions across large production runs and minimizes rework.

Ideal for CNC Machining

CNC machines rely heavily on precise positioning. A self-centering vice complements CNC operations by ensuring accurate alignment with the machine axis. This leads to smoother tool paths, better surface finishes, and reduced programming adjustments.

Enhanced Surface Finish

Proper alignment reduces uneven cutting forces and vibration. With a self-centering vice, the workpiece remains stable during machining, resulting in cleaner cuts, improved surface finish, and less tool chatter.

Versatility Across Applications

Self-centering vices are suitable for milling, drilling, grinding, and inspection tasks. They can handle a wide range of workpiece shapes and sizes, making them versatile tools for tool rooms, R&D labs, and production floors.

Lower Risk of Human Error

Manual centering introduces the possibility of operator error. By automating the centering process, self-centering vices reduce dependence on manual skill, leading to more reliable outcomes even with less-experienced operators.

Improved Tool Life

Accurate workholding reduces uneven tool loading and vibration, which can prematurely wear cutting tools. Using a self-centering vice helps extend tool life, reducing tooling costs over time.

Increased Productivity

When setup time is reduced and accuracy is improved, overall productivity naturally increases. Operators can focus more on machining and less on adjustments, allowing shops to handle higher workloads efficiently.

Cost-Effective in the Long Run

While self-centering vices may have a higher initial cost than standard vices, they save money in the long term by reducing scrap, rework, tool wear, and downtime. This makes them a smart investment for precision engineering operations.

Applications of Self-Centering Vices in Precision Engineering

Self-centering vices are widely used in:

CNC milling and drilling

Precision grinding

Tool and die manufacturing

Automotive and aerospace components

Prototype development and R&D

Their ability to deliver accuracy and repeatability makes them indispensable in high-precision industries.

FAQs

Q1. What is the main advantage of a self-centering vice?

It automatically centers the workpiece, ensuring high accuracy and repeatability while reducing setup time in precision machining.

Q2. Are self-centering vices suitable for CNC machines?

Yes, they are ideal for CNC machining as they ensure perfect alignment with the spindle axis for consistent results.

Q3. Does a self-centering vice improve surface finish?

Yes, proper alignment reduces vibration and uneven cutting, resulting in smoother surface finishes and better quality.

Q4. Can beginners use a self-centering vice easily?

Yes, it reduces manual alignment effort, minimizing human error and making it user-friendly for less-experienced operators.

Q5. Is a self-centering vice worth the investment?

Absolutely. It reduces scrap, rework, tool wear, and downtime, making it cost-effective in the long run.

Conclusion:

In precision engineering, success depends on the smallest details—and workholding is one of the most important. A self-centering vice offers unmatched accuracy, faster setups, improved repeatability, and long-term cost benefits. For professionals looking to upgrade their machining efficiency, investing in reliable workholding solutions is essential.

Buyohlic offers high-quality self-centering vices and precision tooling designed to meet modern manufacturing demands. With a focus on accuracy, durability, and performance, Buyohlic supports engineers and machinists in achieving consistent, high-precision results across every project.